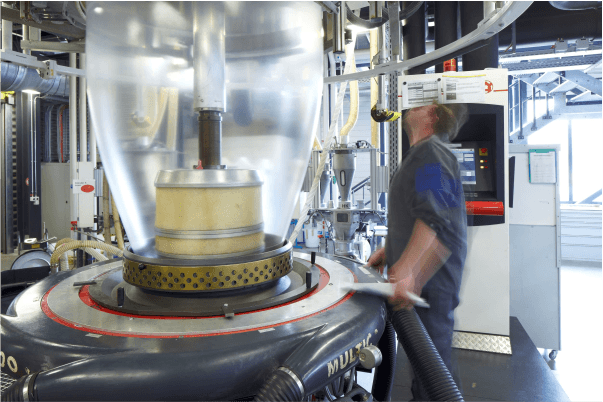

Blown Film Application

Blown Film Application

Plasmix Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. It helps to enhance the strength of the product, Flexibility of production is endless because of the wide range of material and color. It reduced waste and low labor costs. Plasmix Masterbatch provides customized products as per customer requirements.

Blown film is another extrusion processes used to fabricate film products. In this case the extrusion die is shaped as a circle and air pressure is used to further expand the film. After it is expanded to the desired dimensions it is cooled to solidify the polymer.

Blown film extrusion is extensively utilized to fabricate packaging film, much of which is multilayered to improve mechanical, transport, and thermal properties as required by the food or medical industry.

Monolayer Films

Made of LDPE, LLDPE, HM HDPE, etc are cost effective , widely used for various Industrial applications such as Packaging films, Protection film, Shrink & Cling films, Water pouches, Paper match film, Stretch film, Dust covers , Liners for bags, Agricultural film, Barrier film for food packaging, HM carry bags etc.

Multilayer Films

Made with LDPE , LLDPE , HDPE are of 4 types as given below : A-B Type 2 layer blown films are cost effective and widely used in applications such as Agricultural films, Mulch film, Construction films, Detergent bags, Heavy duty bags, Shopping bags, Garment packaging, Shrink film etc.

Multilayer Films

5 layer PE blown film has the combination of skin & core layers with diverse film properties , significant capabilities and cost advantages when compared to conventional 3-layer films. It has wide applications in collation shrink films , laminates , edible oils, ghee etc.

Advantages of Using

Masterbatches for Blown Film Solutions

- Blown films have more balanced in mechanical properties than simple or extruded films because it passes through various machines and traverse directions. Stretch film manufacturers also make sure that the thin film produced is tensile, flexible, and robust.

- A large film, two smaller thin films, or other shapes of the film can be produced via blown film extrusion.

- Excessive trimming is not needed after the film is manufactured, and a single die can be used to make different shapes and sizes of the film.

- Compared to the cast extrusion, the lower melting temperature is required in blown film extrusion. It reduced the cost of manufacturing.